ZG cold chamber die casting machine 180T-850T

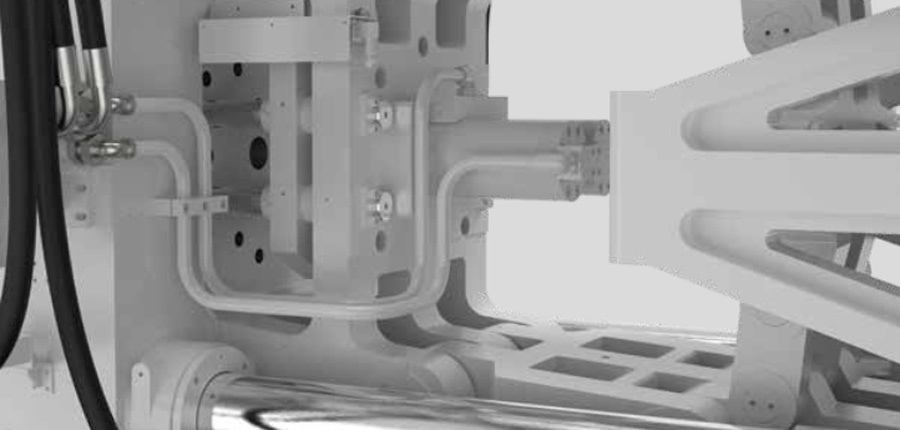

в—Һ Dual closed-loop real-time control injection system (optional)

Equipped with fast inlet servo valve + fast outlet servo valve + booster outlet servo valve to realize double closed-loop control of pressure and speed.

в—Һ Semi closed-loop injection system (optional)

Equipped with electric control valve + injection curve to realize the automatic adjustment of speed I, speed II and boost speed, and automatic correction; at the same time, it can display the pressure, speed, position and other curves, and record the injection data.

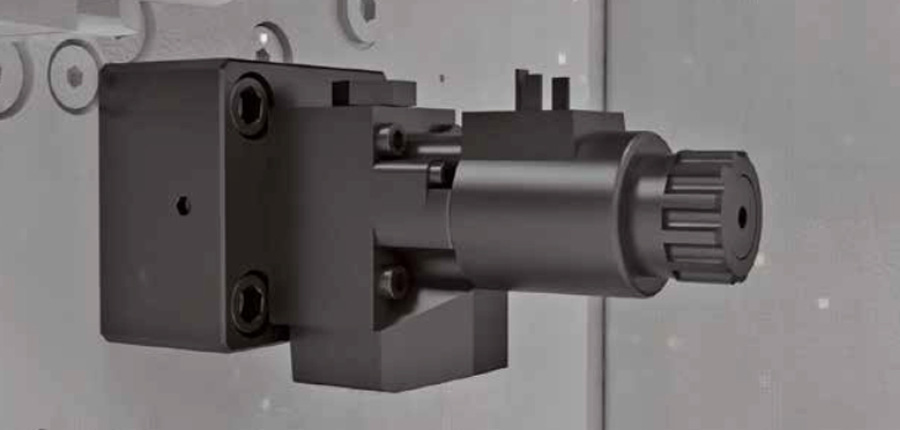

в—Һ Customized second fast valve

The fast response valve specially developed for the speed II acceleration performance of the die casting machine has faster, more stable and more durable injection speed.

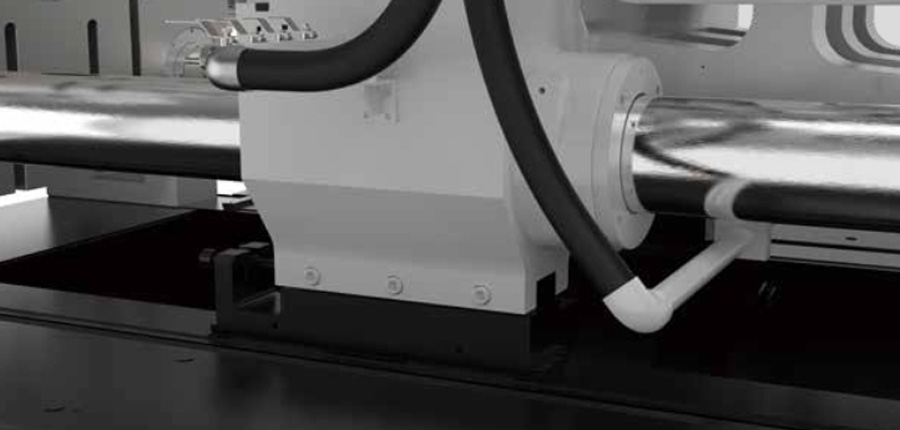

в—Һ Thickened enterprise board

The thickened enterprise board and the thick pull rod are conducive to maintaining the coaxial degree of injection for a long time.

в—Һ Automatic pressure relief of accumulator

Equipped with quick/boost accumulator unloading valve, it can realize automatic pressure relief of shutdown accumulator with high safety.

в—Һ Active oil temperature cooling

Active cooling with an independent cooling pump drawing oil from the oil tank to circulate cooling, making the cooling more reliable. (servo)

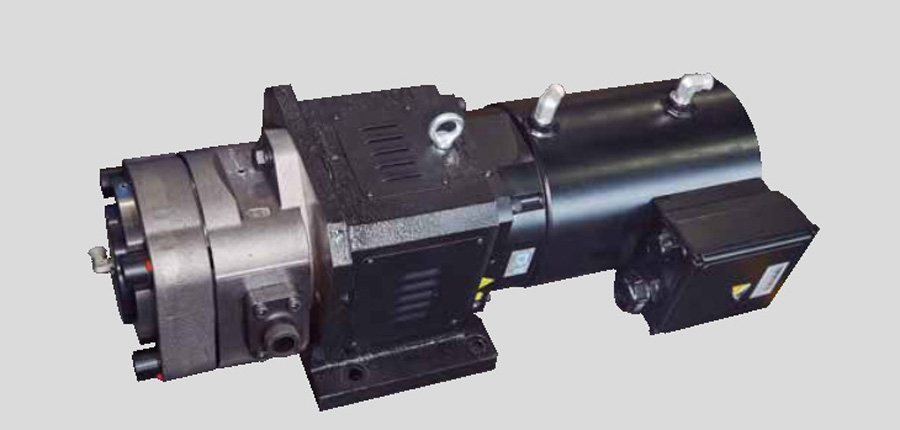

в—Һ High performance servo system

Adopting Zhengao high performance servo system with remarkable energy saving and configured with efficient and stable oil cooling method. (servo)

в—Һ Intelligent Keba computer control system

Equipped with the mold locking force display (servo), injection curve and intelligent quality online function of the whole machine, it has a 12 Inch Touch screen with powerful function, stable performance, good expansibility and long service life.

в—Һ Two-in-one independent electric box

The main control electric box and servo electric box are combined into one,realizing the integral hoisting. After installation, it is separated from the frame without vibration interference.

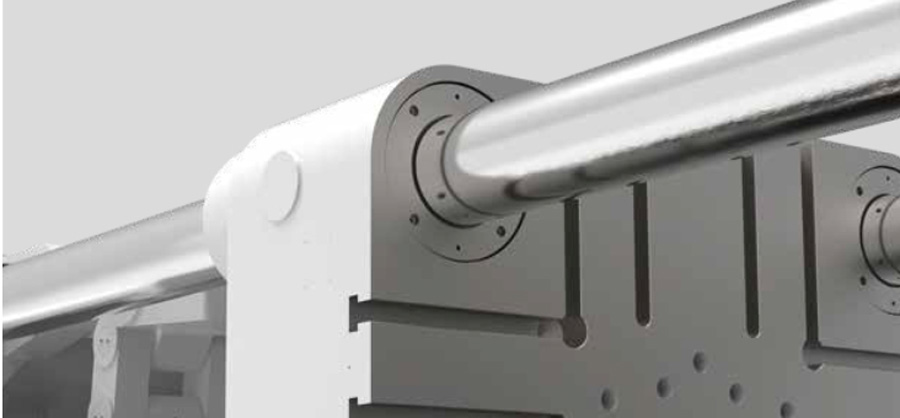

в—Һ Special tie bar

The tie bar is made of special materials developed by the Zhengao Materials Research Institute, with an enlarged diameter, good stress and strong rigidity. After years of practical use, it can significantly extend the service life of the pull rod.

в—Һ High-performance lock shaft

The lock shaft is made of 38CrMoAl material and is nitridated, with a large diameter,high strength, good toughness and long service life.

в—Һ Adjustment nut

The adjustment nut is made of inner pouring aluminum bronze, which has higher mechanical properties, wear resistance, corrosion resistance, cold resistance, heat resistance and no ferromagnetism; it has good antifriction, good elongation and long service life; it can ensure smooth mold adjustment, effectively prevent mold adjustment from not moving, and protect pull rod thread.

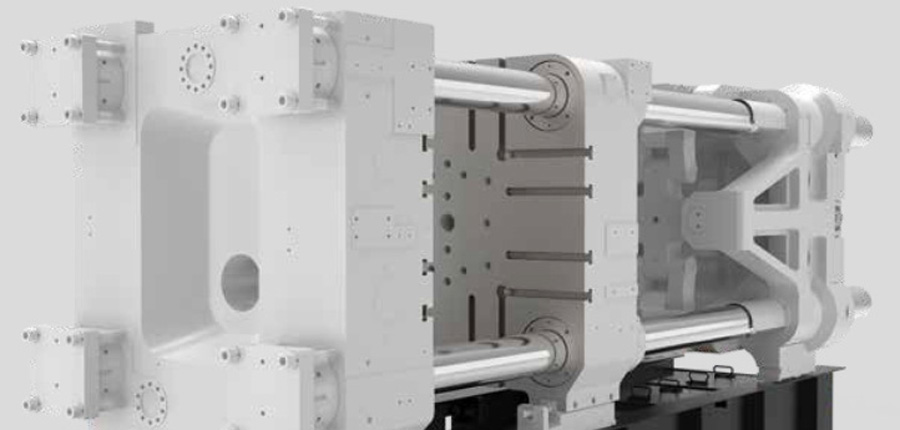

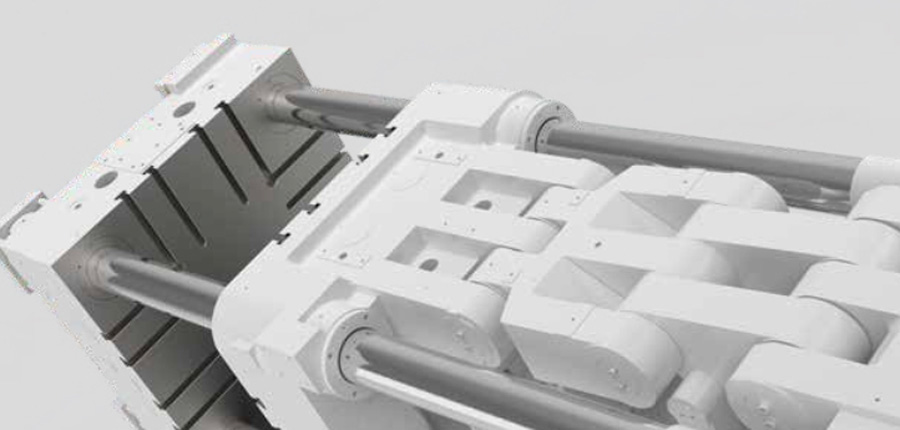

в—Һ Thickened three platens

Thickened three platens have high strength, good wear resistance and small deformation.

в—Һ Stiffener structure of middle plate

The structure of supporting rib plate is added to the middle plate, which effectively reduces the deformation of the middle plate, and fixes the ejector cylinder on the rib plate, which solves the problems of ejector cylinder swing,uneven ejector force, broken ejector pin, broken ejector cylinder piston rod,etc.

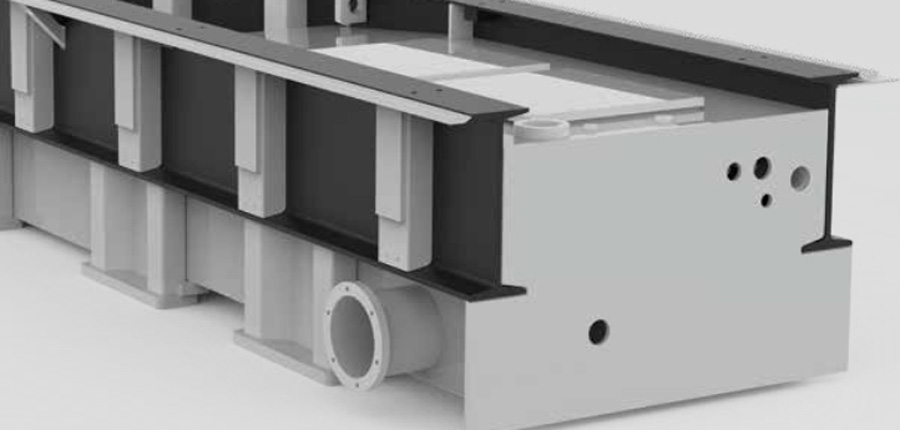

в—Һ Machine body design

The machine body is of high-strength I-beam structure. The centerline of the sliding foot of the template and the center line of the upper and lower tie bars are in the same plane with the I-beam support bar. After annealing treatment,the anti-twisting ability and rigidity of the frame are greatly enhanced, whichensures the overall accuracy of the machine for a long time.

в—Һ Mold closing motion analysis

Through the analysis of ZhengaoвҖҷs unique hinge motion software, the five-point mechanical structure is optimized and advanced slope control mode is adopted to make the energy output curve of the pump station system, the motion curve of the mold locking cylinder and the motion curve of the mechanical hinge be almost perfectly matched; within the range of the mold opening stroke, the middle plate can stop at any position within the opening stroke and with high repetition accuracy, effectively shortening the production cycle.

в—Һ Intelligent mold adjustment structure

Equipped with automatic mold adjustment function, the hinge can be extended to adjust the mold. The mold adjustment motor is equipped with a self-locking function, which effectively solves the problem of the reduction of the clamping force caused by the retreat of the mold closing mechanism, and better guarantees the stability of the product.

в—Һ Extended guide sleeve structure

The extended guide sleeve structure of middle plate can ensure more smooth and reliable operation of middle plate.