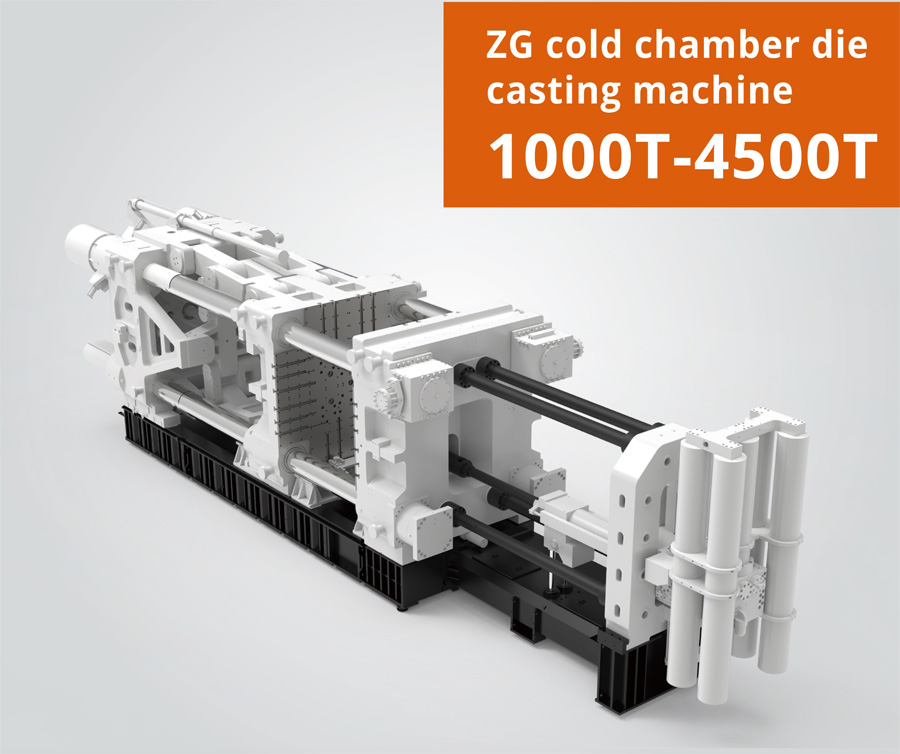

ZG cold chamber die casting machine 1000T-4500T

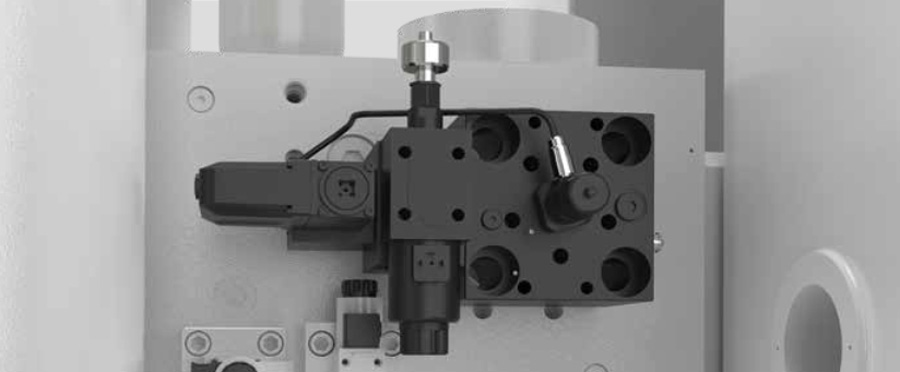

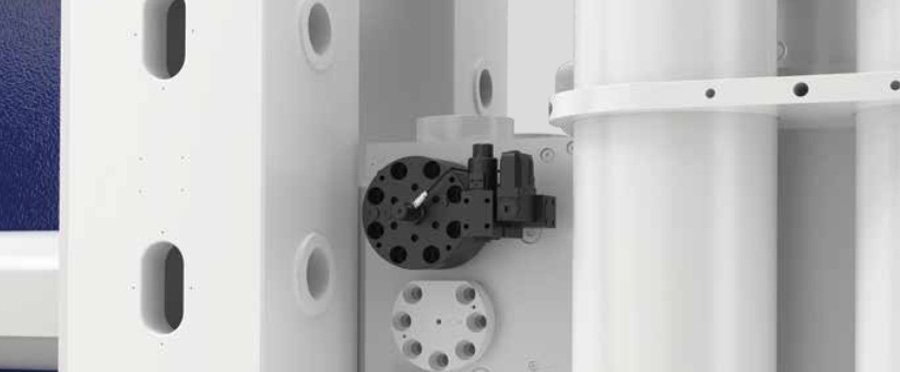

◎ Double closed-loop full real-time control system

Equipped with fast inlet servo valve + fast outlet servo valve + booster outlet servo valve to realize fast double closed loop control of pressure.

◎ High system pressure

The pressure of the system can reach 210bar, the reaction speed of the whole machine is faster and the performance is better.

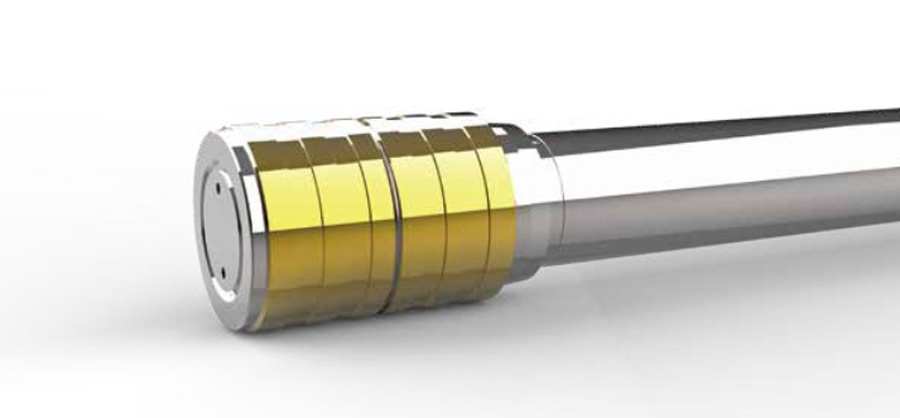

◎ Large material cylinder piston

The exclusive rigid welding structure can reduce the friction resistance in the process of movement, reduce energy loss, effectively avoid the internal leakage caused by the pulling of the injection cylinder and prolong the service life of the seal.

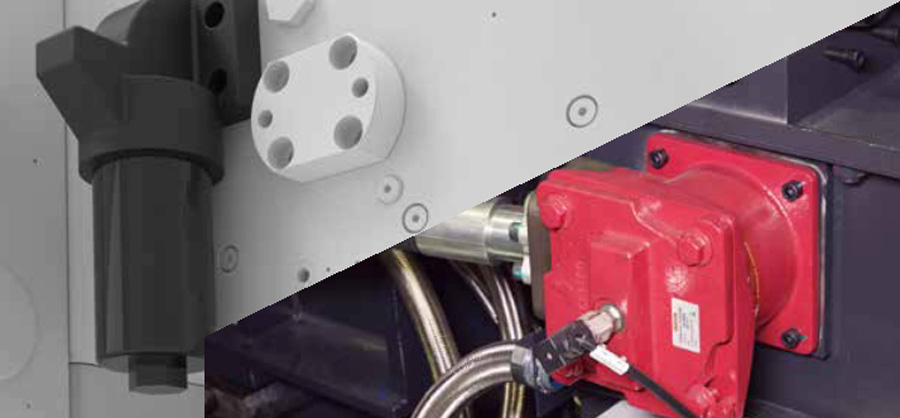

◎ Multiple hydraulic oil filtration

Equipped with oil suction filter, outlet high-pressure filter, bypass filter, corepulling oil return filter, injection servo filter, etc., it can greatly improve the protection of hydraulic oil cleanliness and ensure the reliable work and service life of hydraulic components.

◎ Detection and control of hydraulic oil

Equipped with multiple oil temperature and oil level display and alarm, and equipped with automatic oil temperature preheating function and independent pump active water cooling system, oil temperature control is more reliable.

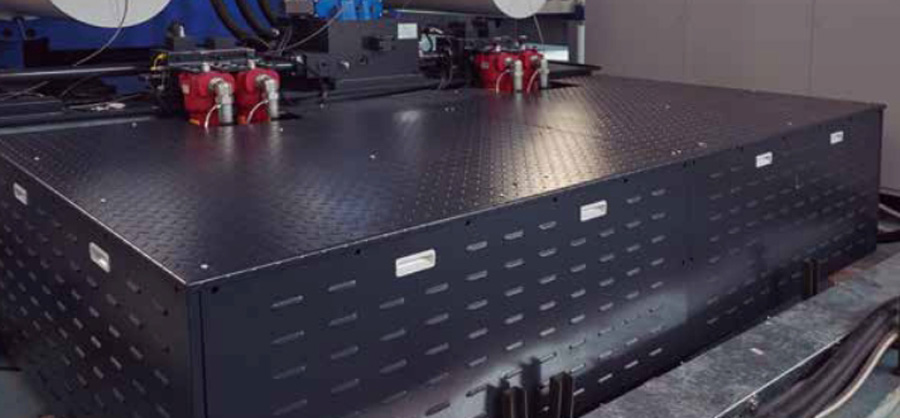

◎ Design of independent oil tank

The independent oil tank structure and paint baking process are more favorable to the hydraulic system, and the oil change and maintenance are more convenient.

◎ Substation mode

The industry's first to use the mode of substation mode (IO distributed), which is more stable and anti-interference; multiple CPU partitions are independently controlled and the circuit is simplified, making the signal transmission faster.

◎ High performance servo system

Adopting Zhengao high performance servo system with remarkable energy saving and configured with efficient and stable oil cooling method.

◎ Upgraded tie bar material

CL516, which is newly developed by Zhengao Materials Research Institute, has higher strength and better toughness.

◎ Auxiliary template

The movable and fixed platen mold surfaces are equipped with P20 mold steel (auxiliary templates), completely solving the long-standing industry issue of mold surface indentation. This also enhances the rigidity of the templates (optional for models 1000 and 1300).

◎ Hydraulic pulling rod

Hydraulic pulling rod is above the operation side; the installation position of the hydraulic pulling rod above the non-operation side is reserved for self-selection.

◎ Intelligent KEBA control system

High performance hardware and rich functionality software systems can collaborate with various peripheral devices and MES digital factories (OPC-UA) to provide customers with precise and efficient control solutions; The 18 inch multi touch screen provides a better user experience with its simple operation.

◎ Mold opening and closing control

The large flow proportional valve is used to control mold opening and closing,making the mold opening and closing reaction faster and the position more accurate. At the same time, the clamping hydraulic safety valve is configured,making the clamping safety protection more reliable.

◎ Ejector mechanism

The ejector position is controlled by MTS magnetic scale + travel switch, which is a dual configuration for easy switching.

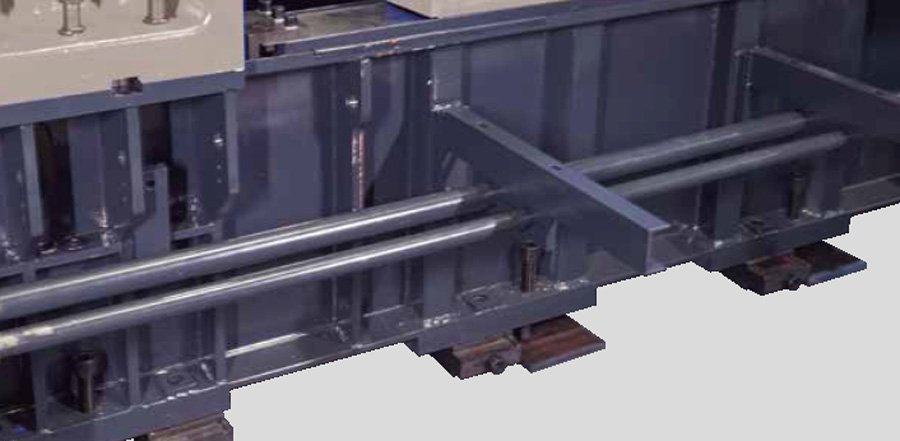

◎ High-strength body

Exclusive use of I-beam or H-beam structure frame, and the overall annealing stress relief, good force, rigidity, good resistance to eformation.

◎ Multiple security facilities

Equipped with safety module, front door safety grating, life safety lock, mold locking confirmation, machine hinge grating protection and multiple emergency stop switches, making operation safety more secure.