Guangzhou Zhen Gao Die-casting Machine Co., Ltd. was established in the year of 1993, and it is mainly in manufacturing hot chamber & cold chamber die casting machine. In the year of 1996, in an only one-time national wide, among monitoring draw-checking for product quality, it runs Number one in the profession. In the year of 2002 again, it is evaluated as “Excellent quality brand”, by the China Technology Monitoring Information Association. In the year of 2004, our “Zhen Gao” Cold Chamber & Hot Chamber Die Casting Machine are evaluated as “Qualified Products in National Quality Checking”, by China Quality Checking Association. Nowadays, “Zhen Gao” is already become a wellknown leading brand in domestic market of die casting machine. Zhen Gao die casting machine has owned CE. The products are well sold to all places in China, and also as far as to many countries, such as Europe, South America,Africa,Russia ,Middle-East, and South-East Asia.

Followed with the principle of “Customers are honored and Precision is reached for after precision,” quality and service management is further enhanced. We have the ability to provide high quality machine and good service. Take high tech & excellent quality as a tenet, and provide for customers with superior machines at performance vs prices. Zhen Gao will be more and more professional!

ZHENGAO’S HISTORY

IN Sep,2012

Bao Helin, chairman of Guangzhou Huayan Precision Machinery Co., Ltd., is a wholly-owned acquisitions, and renamed “Guangzhou Zhen Gao Diecasting Machine Co.,Ltd. ” continue to serve customers.

IN 2009-May,2012

Guangzhou Machinery Engineering Research Institute (China mechanical equipment group Company) become a wholly owned holding company. CCM series cold chamber machine (380T-680T) was successfully developed and put into the market.

IN 2009

Adopted ISO9001 certification

IN 2006

Awarded Guangdong famous brand .

IN 2005

Fast melt and energy-saving furnace ,awarded national patent .Awarded CE certification . The first CCM series (130-280T) cold chamber machine was successfully developed and put into the market.

IN 2004

Evaluated as “Qualified Products in National Quality Checking”, by China Quality Checking Association

IN 2003-2008

Hong Kong Chen Hsong out of fund stock,and remain technical stock ,instead by Guangzhou Machinery Engineering Research Institute (China mechanical equipment group Company) holding 75% shares, and the remaining shares by Australian, American composition.

IN 2002

Evaluated as “Excellent quality brand”, by the China Technology Monitoring Information Association .

IN 1996

In an only one-time national wide, among monitoring draw-checking for product quality, Zhen Gao runs No.1 .

IN 1993-2003

Hong Kong Chen Hsong Group and Guangzhou Machinery Institute (formerly China Machinery Industry Ministry of enterprise) joint venture,set up “Zhen Gao” company , specializing in manufacturing die casting machine.

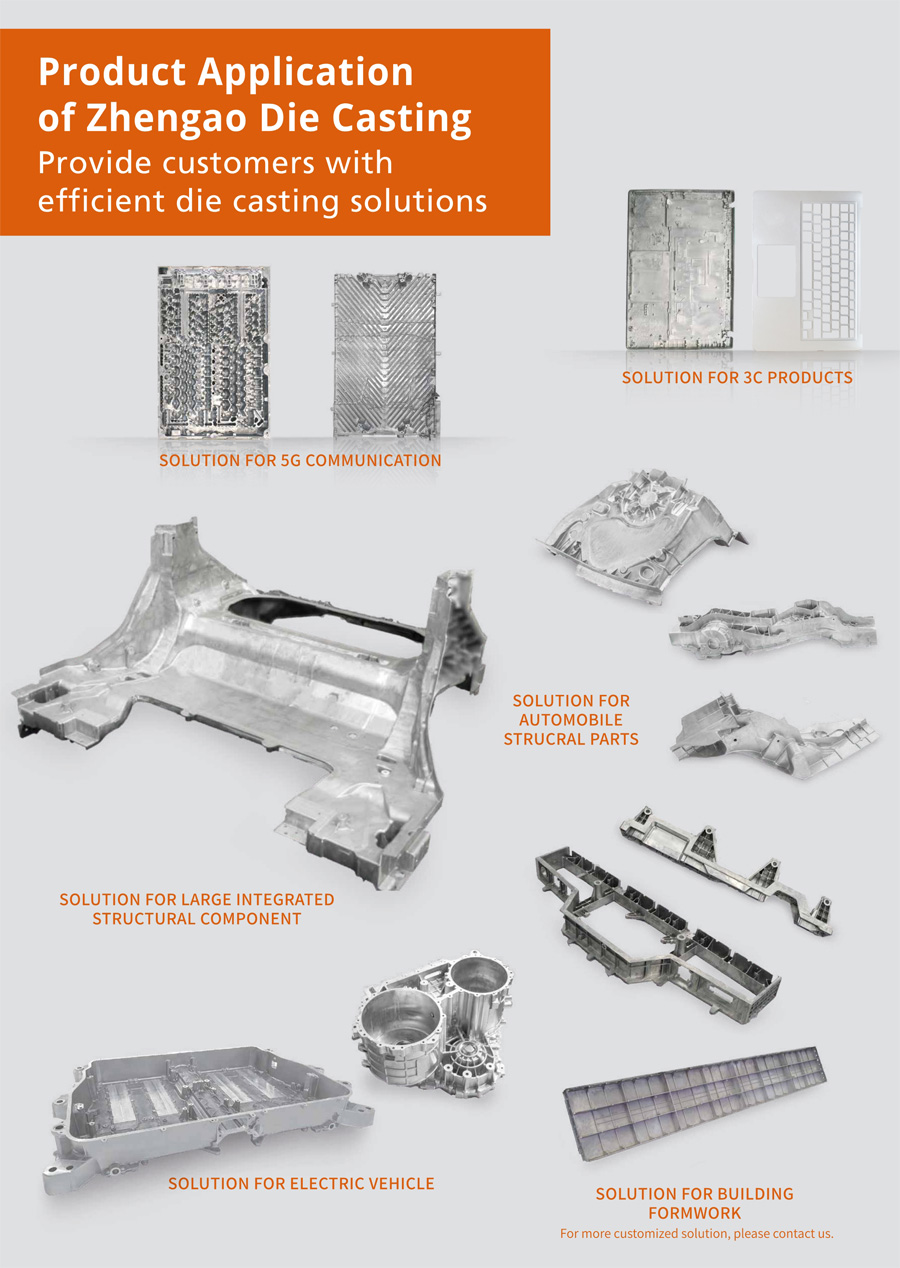

Product Application of Zhengao Die Casting

Provide customers with efficient die casting solutions

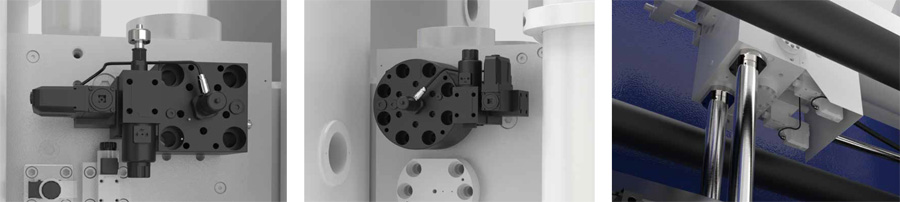

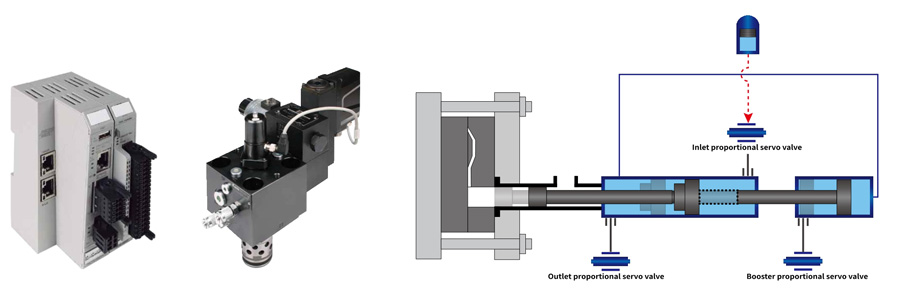

Dual closed-loop full real-time control injection system(optional)

ZG cold chamber die casting machine series

Zhengao Die Casting’s newly developed next-generation dual closed-loop real-time control injection system utilizes an advanced control

system to achieve closed-loop control of casting pressure and injection speed. It also provides closed-loop control of intensification

pressure and pressure build-up time, with the intensification pressure adjustable in six stages. This system enables a high-quality, highly

stable, and perfect injection process, offering ideal equipment support for the production of high-precision, high-quality die-cast parts.

Performance of dual closed-loop full real-time control injection system

• 0.25ms real-time control cycle

• With uniform acceleration function

• Configurable ten-stage injection speed, six-stage intensification pressure, wider process adjustment range

• ±1bar intensification pressure real-time control and intensification pressure repeat accuracy

• 0.05m/s-8m/s stepless adjustment for Injection speed, superior acceleration with ultra-low speed extrusion function

• Closed loop control of pressure with very short build-up time

• Excellent high speed repetition accuracy and slow speed repetition accuracy

• With end brake to realize the injection without flash

• Start without impact